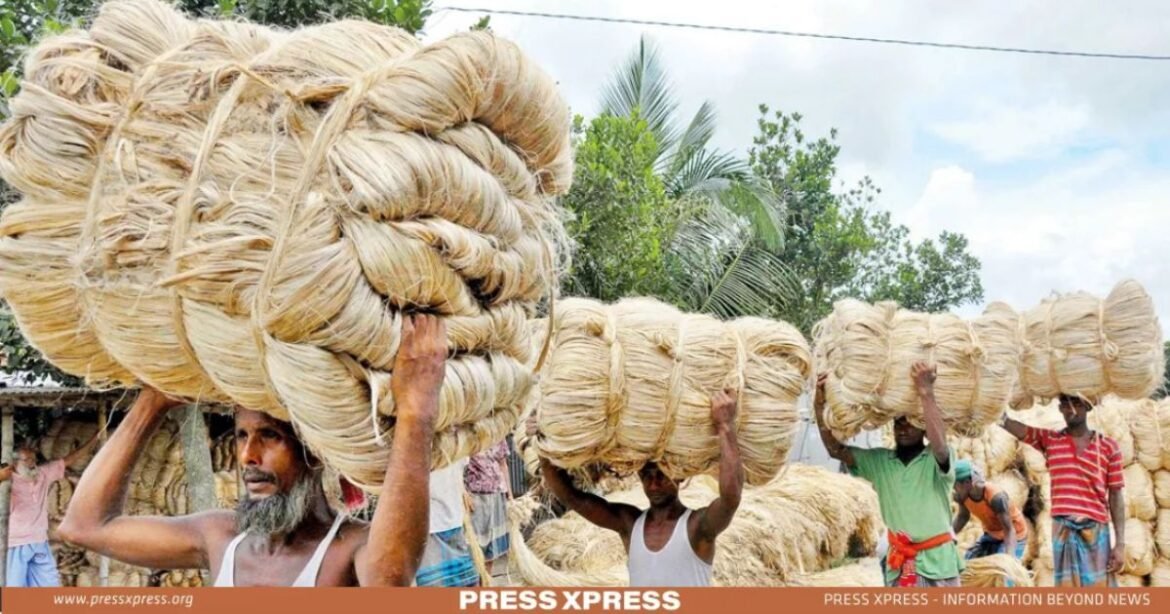

Throughout the ages, people have harnessed the versatile qualities of jute to create a wide array of products, valuing its affordability, biodegradability, and eco-friendliness. In the heart of Bangladesh, jute is affectionately dubbed the ‘golden fiber.’ The International Market Analysis Research and Consulting (IMARC) Group’s data suggests that the market for jute bags is projected to hit $3.84 billion by 2027, boasting a 10.4% Compound Annual Growth Rate (CAGR). In Bangladesh, the jute sector not only contributes 1% to the nation’s GDP but also constitutes 3% of the total export earnings.

The jute along with textile industries are significantly boosting the nation’s economy. They are the primary source of export earnings. Notably, about 80% of the textile workforce is composed of women. These industries contribute to rural poverty reduction, women’s empowerment, and the creation of jobs that bring in foreign exchange for the country.

Furthermore, the ongoing initiative involves the implementation of a smart government approach through the digitization of various services within the Ministry of Textiles and Jute.

Department of Textiles Leading the Way

In 2017, the Directorate of Textiles, which is responsible for overseeing the textile industry, underwent a major transformation and was upgraded to the Directorate of Textiles. This department plays a crucial role in developing a skilled workforce in the textile sector and leading development projects to strengthen the industry. There are currently 9 Textile Engineering Colleges, 14 Textile Institutes, and 41 Textile Vocational Institutes, all focused on meeting the challenges brought by the fourth industrial revolution in the textile industry.

Some Key Highlights of the Textile Sector

- The ‘Textile Industry (Registration and One-Stop Service Center) Rules’ in line with the Textile Act of 2018 and 2021 have been officially published in the Gazette

- The textile industry sponsoring authority has received 50,282 applications through the one-stop service and processed 49,470, achieving a commendable progress rate of 98.39%

- From 2013 to June 2023, the parent authority has collected and deposited Tk 1,300.23 lakh in non-tax revenue into the government treasury

- Under the guidance of the sponsoring authority, a total of Tk 18,925,387.072 has been invested, with local investments of Tk 18,759,003.000 million, foreign investments of Tk 89,351.015 million, and joint investments of Tk 77,033.057 million

- Efforts to connect the Directorate of Textiles and the NISE (National Intelligence for Skills, Education, Employment & Entrepreneurship) data platform are in progress

An in-depth analysis of the current state of textile technology education has led to the development of a detailed action plan- Enterprise Resource Planning-ERP. This plan is designed to guide the development of a skilled workforce for the textile and ready-made garments industry in the next 30 years.

Training programs under ERP include:

- Skill Development Initiative Under Department of Textiles to tackle 4th Industrial Revolution

- Training on Computer Aided Design (CAD)

- Computer Aided Manufacturing (CAM) Application on Computerized lain and cutting machine

- Textile Education and Resource Planning (TERP)

Further aspects of digitization involve:

Bangladesh’s Jute Powerhouse on the World Stage

In the present age of sustainable development, the Jute Directorate is actively engaged in promoting the global demand for eco-friendly jute and jute products. Their endeavors encompass a comprehensive approach, including the provision of policy support to various stakeholders such as jute farmers, jute product manufacturers, entrepreneurs specializing in multi-purpose jute products, as well as organizations involved in the export of jute products.

Major importing countries include:

- Australia

- Belgium

- Brazil

- China

- Djibouti

- Germany

- India

- Indonesia

- Ivory Coast

- The Republic of Korea

- Pakistan

- Russia

- The United Arab Emirates

- The United Kingdom

- The United States

- Vietnam

Bangladesh takes pride in its extensive range of 285 jute products, which are exported to more than 100 countries worldwide. These products range includes raw jute, jute hessian, bags, sacks, ropes, carpets, caps, mats, carpet backing cloth, chair covers, jute sheets, canvas, pulp and paper, household items, and non-woven textiles, among other items. Jute stick charcoal products, a byproduct of jute sticks, are also part of this industry, with Bangladesh producing roughly 3 million jute sticks annually. The country stands to gain between USD 3.0 to 3.5 billion in potential exports from jute stick-based charcoal.

With the introduction of the Packaging Act in 2010, the government sought to encourage the utilization of eco-friendly jute products in lieu of polythene or polypropylene bags. This approach offers a significant way to introduce jute into the local market.

Achievements of Jute Industry:

- The Directorate of Jute oversees the Advanced Technology Jute and Jute Seed (1st Revised) project. It aims to boost jute production, reduce reliance on imported seeds, and train farmers in modern cultivation which benefits 600,000 farmers in 230 upazilas across 46 districts, providing them with Ufshi jute seeds, fertilizers, pesticides, machinery, and free training.

- The government aided jute farmers to achieve a target of 89.87 lakh bales of jute on 18.87 lakh acres for the current season. (2022-2023)

- Vigilance efforts during the jute season include preventing illegal hoarding, discouraging wet jute sales, and taking legal action against unlicensed businesses, ensuring fair prices for jute farmers.

- The ‘Compulsory Use of Jute Wraps Act’ helps in reducing environmental pollution by increasing domestic jute product usage.

- Introduced online licenses for jute businesses to enhance transparency, accountability, and revenue collection, contributing to Bangladesh’s development.

- Jute traders benefit from the services offered by the existing three quality testing laboratories for jute and jute products.

A Glance at Bangladesh’s Rich Textile Heritage

Handloom or weaving is a cherished tradition in Bangladesh’s cultural heritage, offering livelihoods to many people and serving as the second-largest employer in rural areas after agriculture. This sector employs 1.5 million people, including 900,000 directly and 600,000 indirectly, making it a crucial driver of sustainable employment and economic growth. Additionally, it has played a significant role in empowering women by providing them with valuable employment opportunities.

Textile Training Initiatives in Bangladesh:

- Establishment of ‘Handloom Textile Equipment Development Center (CHPED)’ in Sahepratap, Narsingdi.

- 3 Fashion Designing Training Sub-centers at:

- Belkuchi, Sirajganj

- Kamalganj, Moulvibazar

- Kalihati, Tangail

- 01 Handloom Training Center at Khadimnagar, Sylhet for Manipuri weavers

- 1 weaving training center at Khasbag Satmatha, Rangpur city for marginal weavers in the north

- 1 training sub-center in Pabna district

Objectives:

- Hands-on training in various looms, yarn dyeing, design, block and batik printing, tie and dye, etc.

- Goal: Increase production of high-quality woven fabrics and develop weaver skills with new designs.

Progress:

- CHPED Narsingdi transformed into ‘Bangladesh Tant Shiksha Training Institute’.

- Introduction of a 04-year diploma-in-textile engineering course from the financial year 2010-11.

- Later, the addition of a 04-year B.Sc-in-Textile Engineering course started from the financial year 2019-20.

A project was initiated in 2018 to revive the illustrious Dhakai Muslin, which had been lost for approximately 170 years under the leadership of Sheikh Hasina. Building on these initiatives, the Bangladesh Weaving Board has introduced advanced technology for crafting exquisite muslin sarees. This innovation stems from the identification of specific cotton varieties ideal for producing muslin yarn, along with producing yarns ranging from 300 to 750 counts.Hasina.

On October 12, 2014, Prime Minister Sheikh Hasina during her visit to the Ministry of Textiles and Jute, expressed, “Bangladesh has a rich tradition in the textile industry, with historical roots in muslin yarn production in certain regions. It is imperative that we undertake initiatives to revive and preserve this valuable textile technology.”

Rajshahi silk fabric is another gem in our textile heritage. In 1974, the Father of the Nation, Bangabandhu Sheikh Mujibur Rahman, was intrigued by the quality of Rajshahi silk cloth during a visit to Uttara Ganabhaban in Natore. He expressed his determination to establish an independent institution to promote and develop the silk industry which later led to the establishment of the Bangladesh Silk Board.

Undertakings and accomplishments of Bangladesh Handloom Board

- ‘Dhakai Muslin House’ has been established in the Tarab Municipality of Narayanganj.

- The Bangladesh Textile Board received the GI certificate for muslin from WIPO.

- The Bangladesh Handloom Board won the Public Administration Medal-2021 for this extraordinary effort.

- Alochya Muslin Project trained 350 skilled weavers and spinners.

- Efforts are underway to promote Dhakai Muslin globally and boost Bangladesh’s international image.

Bangladesh Silk Development Board Achievements

- Key Developments:

- 7 Mulberry Plantations

- 11 Silk Nurseries

- 20 Chawki Rearing Centers

- Total land for Grainage: 420 Acres

- Innovations in Mulberry Cultivation:

- High-yielding Mulberry Cultivators Developed

- Year-round Mulberry Cultivation

- Germplasm Bank:

- 20 Mulberry Varieties Preserved

- 30 Silkworm Varieties Preserved

- Improved Productivity:

- Increased Mulberry Leaf Production:

- Before: 37-40 Metric Tons per Hectare

- Now: 40-47 Metric Tons per Hectare

- Enhanced Silkworm Production:

- Before: 40-50 kg per Hundred Eggs

- Now: 70-80 kg per Hundred Eggs

- Increased Mulberry Leaf Production:

Conclusion

Bangladesh’s rich textile heritage, driven by the versatile qualities of jute and a strong commitment to eco-friendliness, is not only a source of immense pride but also a significant contributor to the nation’s economic growth. As we admire the renaissance of Dhakai Muslin and the splendor of Rajshahi silk, it is evident that Bangladesh’s textile legacy is not just a thing of the past but a beacon for the future, where tradition meets innovation, and economic prosperity meets environmental sustainability.