India’s journey to becoming a $10 trillion economy by the next decade is set to be powered by growth in key manufacturing sectors. These include the burgeoning fields of semiconductors, electronics, electric vehicles (EVs), renewable energy, and defense. This projection comes from a comprehensive report by Boston Consulting Group and Matrix Partners.

The electronics market is poised to hit the $500 billion mark, while the semiconductor sector is expected to expand to a $120-billion industry by 2030. India has seen a surge in investment from global giants such as Foxconn, Dell, Samsung, Micron, Renesas, and Microchip, thanks to supportive government policies and robust domestic demand.

You Can Also Read: India announces seven-phase general election from 19 April

Opportunities abound in the design and development of graphic processing units and microcontrollers within India, leveraging the nation’s competitive cost structure. The report also notes the potential for localizing the manufacturing and assembly processes, aiming for a fully indigenous semiconductor ecosystem.

India’s commitment to clean energy is evident in its push for the electrification of transportation. The report forecasts annual EV sales to reach 14 million units by 2030, spurred by government initiatives like FAME subsidies and the electrification of public transport. Additionally, a significant investment of approximately $140 billion is planned over the next seven years to bolster solar energy infrastructure.

The report sheds light on the prospects for manufacturing cells and components, designing powertrain components tailored to India’s unique landscape and driving conditions, and the vast export possibilities for solar cells and green hydrogen electrolyzers.

The authors of the report express optimism about India’s potential to transform into a significant global manufacturing hub, particularly in the B2B sector.

The defense market in India, projected to grow to $43 billion by 2030, presents substantial opportunities for the design and production of systems and equipment, as well as the supply of components like turbines and heat exchangers to Tier-1 suppliers.

Entrepreneurs in these sunrise sectors are encouraged to capitalize on the existing gaps, focusing on industries with substantial profit margins and sub-sectors where demand is likely to outstrip supply over the next 5-10 years, ensuring a safety margin to weather economic downturns.

The report also highlights the importance of other sectors such as agriculture, specialty chemicals, and railways, which are vital to India’s infrastructure and food security, in contributing to the nation’s $10 trillion economic goal.

The Potential of India’s Manufacturing Sector

India’s manufacturing sector stands as a cornerstone of its economic landscape, contributing approximately 15%to the nation’s Gross Domestic Product (GDP) and engaging about 12% of its workforce. This multifaceted sector spans textiles, pharmaceuticals, automotive, and consumer goods industries.

To boost this key sector, the Indian government has launched initiatives like the “Make in India” campaign, designed to elevate manufacturing’s GDP share and bolster domestic production. Additionally, the establishment of Special Economic Zones (SEZs) aims to draw foreign investment.

Despite these proactive measures, the sector grapples with infrastructural deficits, skilled labor scarcity, and credit access challenges. It also faces a global demand downturn and stiff competition, notably from China.

Yet, these hurdles present avenues for advancement. With strategic and sustainable reforms, the manufacturing sector is poised to sustain its pivotal role in India’s economic progression.

Key Drivers of India’s Manufacturing Sector Growth

Increased Investment: For the fiscal year 2022-23, the Indian government has earmarked a significant investment of Rs.2,403 crore (approximately US$315 million) to propel the Electronics and IT Hardware Manufacturing sector. Additionally, the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles in India (FAME – India) initiative received Rs.757 crore (around US$104.25 million) in the 2021-22 budget.

Competitiveness: India’s industrial landscape is ripe for a major leap, bolstered by a vast semi-skilled workforce, proactive government initiatives like ‘Make in India’, substantial investments, and a burgeoning domestic market. Government incentives, including the provision of free land and uninterrupted power supply, are sharpening India’s competitive edge on the global stage.

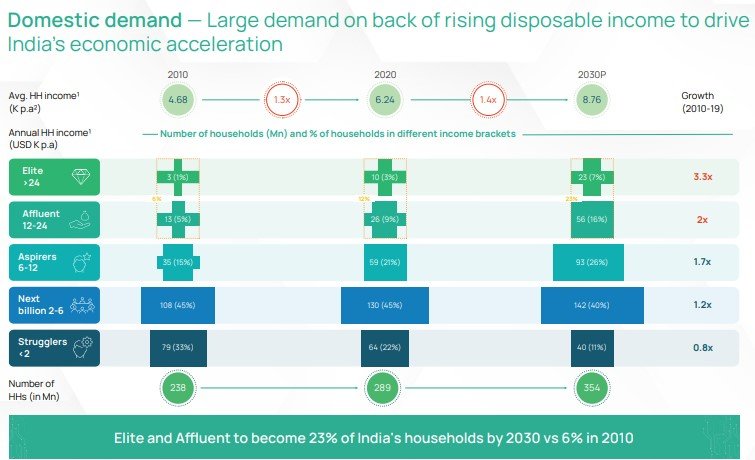

Surging Demand: The Indian middle class is projected to command a significant 17% share of global consumption by 2030. The appliances and consumer electronics (ACE) market in India is on an upward trajectory, anticipated to double from USD 11 billion in 2019 to USD 21 billion by 2025.

Global Hub Aspirations: India’s manufacturing sector is steadily advancing towards Industry 4.0, characterized by interconnected systems and comprehensive data analytics. Indian enterprises are leading the charge in research and development, establishing global dominance in sectors like pharmaceuticals and textiles.

Focus on Automation and Robotics: The industry’s commitment to innovation is evident in its focus on automation and robotics, areas that are garnering significant investment and attention, aligning with the global trend towards smarter manufacturing.

Government initiatives

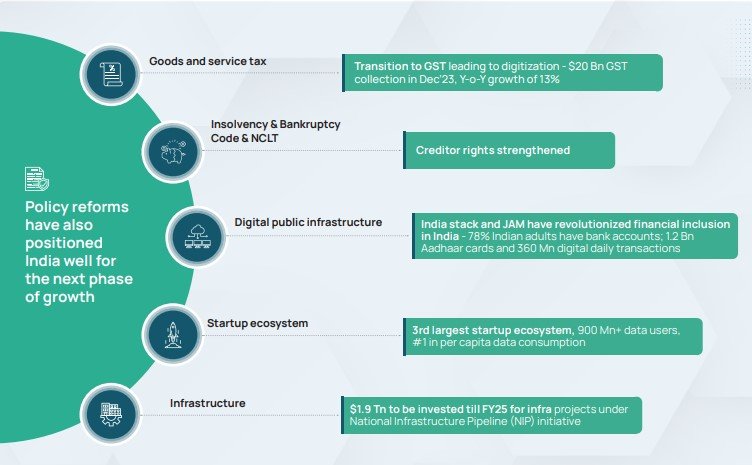

India is making slow but steady progress toward Industry 4.0 thanks to government initiatives and policies including:

- Goods and service tax: Transaction to GST leading to digitization- $20bn GST collection in Dec’23, Y-o-Y growth of 13%.

- Insolvency and Bankruptcy Code & NCLT which strengthen creditors’ rights.

- The National Manufacturing Policy aims to raise manufacturing’s GDP share to 25% by 2025.

- National Infrastructure Pipeline (NIP)

- The PLI scheme for Manufacturing, which was introduced in 2022 and aims to bring India’s core manufacturing sector up to par with international manufacturing standards.

- ‘Make in India’ program to place India on the world map as a manufacturing hub and give global recognition to the Indian economy. The government aims to create 100 million new jobs in the sector by 2022.

- The ‘Atma Nirbhar Bharat’ campaign announced in 2020 was also intended to further boost local manufacturing under its stated goal of making India economically self-sufficient.

- PM Gati Shakti– National Master Plan which is a Multimodal connectivity infrastructure project.

- The PLI for semiconductor manufacturing is set with the goal of making India one of the world’s major producers of this crucial component.

- The government of India’s Ministry for Heavy Industries & Public Enterprises is SAMARTH Udyog Bharat 4.0. This is expected to increase the competitiveness of the manufacturing sector in the capital goods market.

Despite having one of the largest economy in the world, India’s export contribution to global trade is only 1.6%. But this is going to change, buoyed by the government’s robust policy thrust and initiatives. As India emerges as a hub for manufacturing exports, cutting-edge technology and best-in-class workforce are being deployed in the country’s manufacturing domain, giving further impetus to India’s strengths in cost efficiency. Manufacturing is emerging as an integral pillar in the country’s economic growth, thanks to the performance of key sectors like automotive, engineering, chemicals, pharmaceuticals, and consumer durables.