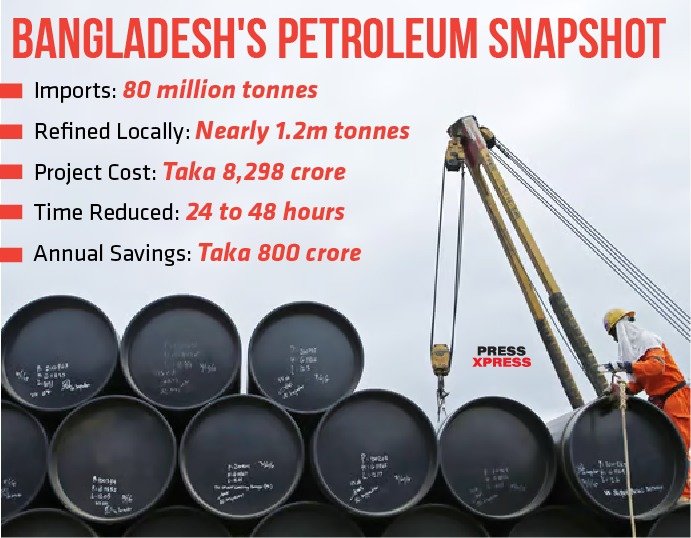

Upon the completion of the single-point mooring (SPM) system installation, along with an underground pipeline, the conveyance of crude oil will be accelerated, reducing the time frame from the previous 12-15 days to just 24 to 48 hours.

Bangladesh has undertaken a sustainable strategy for transporting petroleum products at sea by introducing the Single Point Mooring (SPM) and creating a dual pipeline managed by the state-owned Bangladesh Petroleum Corporation (BPC). This innovative endeavor is poised to modernize the country’s management and transportation of these vital resources.

Of notable significance, the transfer of petroleum products from a main tanker to onshore storage tanks in Matarbari, Maheshkhali upazila, recently commenced. This moment is pivotal as it inaugurates the movement of petroleum products to the Eastern Refinery tanks via a dedicated pipeline.

On November 9, M. Lukman, Managing Director of the Eastern Refinery Limited, announced the arrival of a Saudi Arabian mother tanker carrying 82,000 metric tonnes of ARAMCO crude oil at the outer anchorage of the Bay of Bengal for the SPM commissioning.

Objectives of the project

The primary objectives of the project are to streamline the delivery of imported crude oil and refined products efficiently, at reduced costs, and within shorter timeframes, thereby minimizing system losses associated with the importation process through lighterage operations. It aims to maintain equilibrium between the escalating energy demand and its supply while bolstering petroleum retention capacity by establishing six diesel and crude oil storage tanks at Maheshkhali, consequently fortifying energy supply security.

Mode of transportation of petroleum product

Petroleum transport is the transportation of petroleum and derivatives such as gasoline (petrol). Petroleum products are transported via rail cars, trucks, tanker vessels, and pipeline networks. The selection of transportation method relies on the volume being moved and the intended destination of the petroleum products.

Investment and Future Prospects

While the project’s total cost increased to Taka 8,298 crore due to enhancements in the SPM and double pipeline installation, the long-term benefits far outweigh the initial investment. The project’s success lays the groundwork for future expansions and enhancements in Bangladesh’s energy sector.

“The appointed contractor of the project China Petroleum Pipeline Engineering Co Ltd (CPPEC) has imported the pipeline for replacing the damaged ones caused in the test commissioning in July last,” according to BPC sources.

Towards Sustainable Petroleum Transportation

The test commissioning of the 110 km long double pipeline, designed to transport crude petroleum products directly to Eastern Refinery Limited and the Single Point Mooring, represents a groundbreaking initiative in Bangladesh’s history. While encountering mechanical faults during the initial phase was a setback, the concerted efforts and rectifications made by the project team underscore their commitment to pioneering sustainable transportation methods.

Upon the suspension of the test run due to pipeline faults, the agile response of utilizing lighter tankers from the Bangladesh Shipping Corporation to transport the crude oil showcased a flexible and adaptable approach in ensuring the continuity of operations.

Deadline of the project

The project was originally scheduled for completion by June 2024; however, it has already been finished ahead of schedule. “Under the current arrangement, big ships usually anchor at deep sea at Kutubdia from where lighter vessels receive the imported crude and refined petroleum to carry to the Eastern Refinery (ERL) with the whole process taking 12 to 15 days” sources said. After opening the operation of the Project, the crude petroleum products will be directly pumped to the ERL site.

A Transformative Future

Currently, the Bangladesh Shipping Corporation (BSC) utilizes two lighter vessels to transport imported petroleum products from Kutubdia in the Bay to the ERL site. However, upon the establishment of the Single Point Mooring (SPM) with an underground pipeline, this transportation will be expedited to a mere 24 to 48 hours. According to BPC sources, this installation is anticipated to save a total of Taka 800 crore annually.

The country presently imports approximately 80 million tonnes of crude and refined petroleum fuel annually to fulfill its energy demands, with nearly 1.2 million tons refined at ERL, the country’s sole refinery. This import is expected to surge notably due to the establishment of several fuel-fired power plants in the country.

Conclusion

As Bangladesh embarks on this innovative journey in petroleum transportation, the successful implementation of these initiatives is poised to serve as a beacon of inspiration for similar eco-conscious endeavors globally. The strides taken in this direction affirm that progress and environmental stewardship can indeed go hand in hand, setting the stage for a more sustainable future.